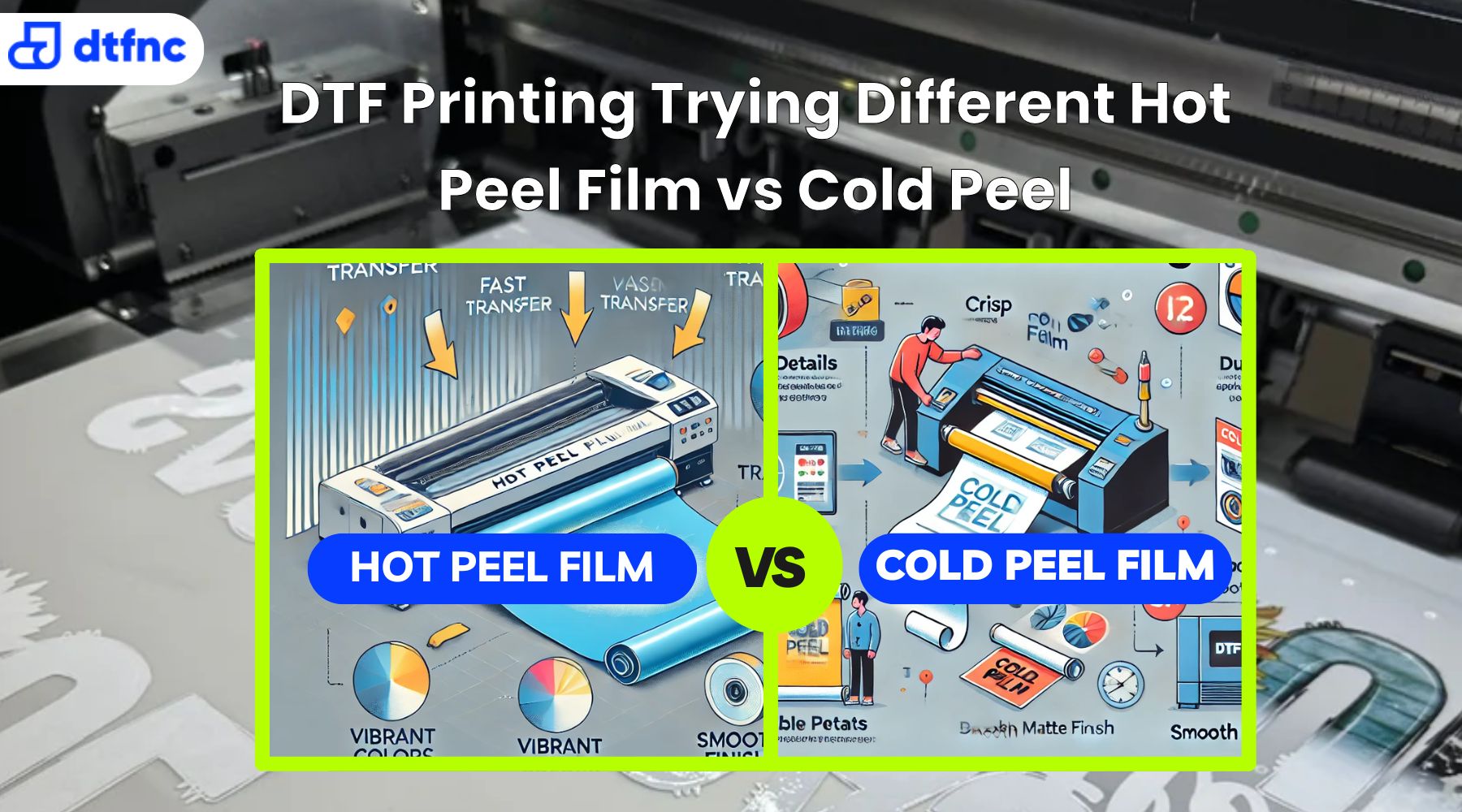

Direct-to-film (DTF) printing has become a game-changer in custom apparel design, offering vibrant prints and flexibility for various fabrics. One of the key decisions in DTF printing trying different hot peel film vs cold peel films. Both have their unique benefits and applications, but knowing the differences is crucial for achieving the best results.

In this blog, we’ll explore the differences between hot peel and cold peel films, their advantages, and how to choose the right option for your printing needs. Let’s dive into the details!

What is DTF Printing?

DTF printing involves printing a design onto a special film, applying adhesive powder, and then transferring the design to a fabric using heat. The two types of peel films used in this process are hot peel and cold peel. The choice between the two significantly impacts the ease of application, finish, and durability of the print.

What is Hot Peel DTF Film?

Hot peel DTF film allows you to peel the film off the fabric immediately after pressing, while it’s still hot. This method is preferred for its speed and efficiency.

Benefits of Hot Peel DTF Film:

-

Quick Application: Saves time by eliminating the cooling period.

-

Smooth Finish: Often results in a glossy and seamless look.

-

Ideal for Bulk Printing: Perfect for large-scale production.

Popular Options:

-

Hot Peel Laviva DTF Film Review: Known for its consistent quality and vibrant prints.

-

Hot Peel DTF Transfers: These are popular for quick-turnaround projects.

Read More: DTF White Ink Composition: Understanding the Secrets to Vibrant Prints

What is Cold Peel DTF Film?

Cold peel DTF film requires the film to cool completely before peeling. This method is ideal for achieving a durable and matte finish.

Benefits of Cold Peel DTF Film:

-

Enhanced Durability: Provides a longer-lasting print.

-

Matte Finish: Preferred for designs that require a subtle look.

-

Reduced Risk of Smudging: Ensures the print stays intact during the transfer process.

Popular Options:

-

Glossy 25 inch Cold Peel DTF Paper: Offers a high-quality finish for professional-grade prints.

-

Wholesale DTF Roll Film Cold Peel Glossy: A cost-effective solution for bulk printing.

Read More: How To Fix Edges in Photoshop for DTF Printing

Key Differences Between Hot Peel and Cold Peel Films

|

Feature |

Hot Peel |

Cold Peel |

|

Peeling Time |

Immediate after pressing |

After the film cools completely |

|

Finish |

Glossy and smooth |

Matte and subtle |

|

Durability |

Moderate |

High |

|

Application Speed |

Faster |

Slower |

|

Risk of Smudging |

Higher |

Lower |

Cold Peel vs Hot Peel: When to Use Each

When to Choose Hot Peel:

-

High-Volume Orders: Saves time during bulk production.

-

Simple Designs: Ideal for projects where durability isn’t the primary concern.

-

Quick Turnarounds: When you need to deliver products fast.

When to Choose Cold Peel:

-

High Durability Needs: For designs that require long-lasting prints.

-

Detailed Artwork: Prevents smudging and ensures intricate designs remain intact.

-

Matte Finish Preference: When a subtle, non-reflective look is desired.

How to Work with Hot Peel and Cold Peel Films

Tips for Using Hot Peel DTF Film:

-

Press the film at the recommended temperature and pressure.

-

Peel the film immediately after lifting the heat press.

-

Use consistent pressure to avoid uneven peeling.

Tips for Using Cold Peel DTF Film:

-

Allow the film to cool completely before peeling.

-

Use a flat surface to ensure the film cools evenly.

-

Peel slowly to avoid damaging the print.

Read More: Can a Epson 15000 Be Used for DTF?

Conclusion

Choosing between hot peel and cold peel films for DTF printing depends on your project’s specific requirements. If you need quick results with a glossy finish, hot peel is the way to go. For enhanced durability and a matte look, cold peel is your best bet. By understanding the differences and applications of each, you can make informed decisions and achieve professional-quality prints.

Looking for reliable DTF printing materials? Visit DTFNC to explore our wide range of hot peel and cold peel films today!

FAQs

Is hot peel or cold peel DTF better?

It depends on your needs. Hot peel is faster and ideal for quick production, while cold peel offers higher durability and a matte finish.

What is the difference between hot peel and cold peel HTV?

Hot peel HTV can be peeled immediately after pressing, while cold peel HTV requires cooling before removal.

How long to wait for cold peel DTF?

Wait until the film cools completely, usually 2-5 minutes.

Why is my DTF not sticking to my shirt?

This may be due to incorrect heat, pressure, or adhesive powder application. Double-check your settings and materials.

Can you overheat DTF transfers?

Yes, overheating can damage the adhesive and affect print quality. Follow the recommended heat settings to avoid this.

11 comments

📂 + 1.648067 BTC.NEXT - https://graph.org/Message--04804-03-25?hs=3002d26048a5185790c4021f0538086f& 📂

1q5icj

📏 + 1.442299 BTC.NEXT - https://graph.org/Message--04804-03-25?hs=3002d26048a5185790c4021f0538086f& 📏

xfo0ir

📀 Notification: Withdrawing №QL80. CONTINUE > https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=3002d26048a5185790c4021f0538086f& 📀

id8j69

🛡 Reminder; TRANSFER 0.75895891 bitcoin. Go to withdrawal =>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=3002d26048a5185790c4021f0538086f& 🛡

ck4ja6

⛏ You have a gift from user. GЕТ =>> https://telegra.ph/Binance-Support-02-18?hs=3002d26048a5185790c4021f0538086f& ⛏

kmkopg