Are you tired of boring, plain hats? Direct to Film (DTF) printing might be the solution you need. DTF printing allows for vibrant, eye-catching designs to be applied directly onto fabric hats.

This guide will take you through everything you need to know about transforming your hats with DTF prints.

Understanding DTF Printing for Hats

Direct to Film (DTF) printing has revolutionized the customization of fabric items, offering a unique way to create vibrant designs directly on hats. Whether you're looking to personalize team gear or create custom fashion pieces, DTF on hats offers versatility and durability.

Benefits of Using DTF Prints on Hats

DTF prints on hats provide several advantages over traditional methods like embroidery or screen printing. They offer:

- Vibrant Colors: DTF allows for rich, detailed colors that pop on fabric, enhancing your hat designs.

- Durability: The prints are long-lasting and withstand washing and wear, making them ideal for everyday use.

- Complex Designs: DTF transfers intricate designs accurately, capturing fine details that other methods might struggle with.

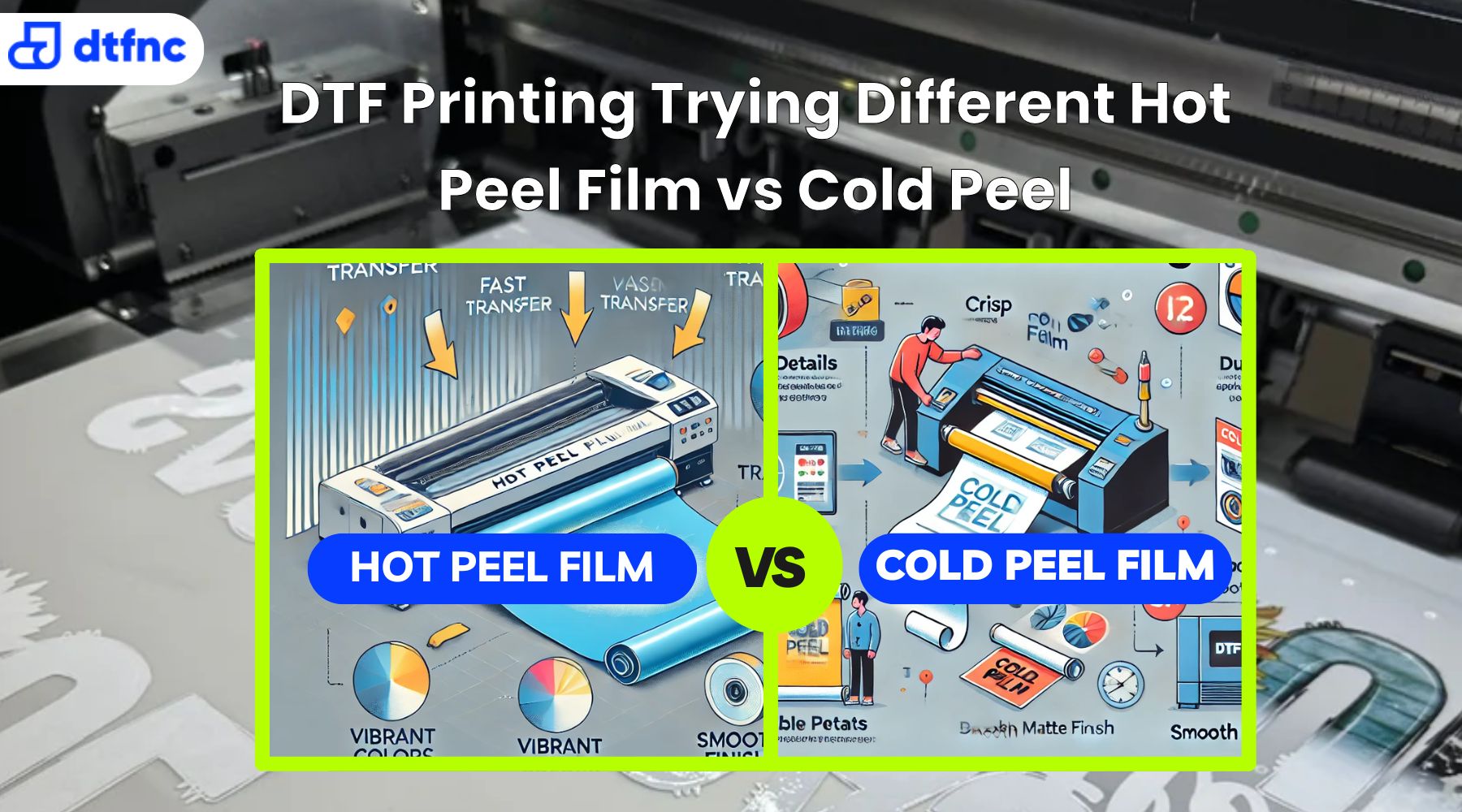

Also Read: How to Cold Peel DTF Transfers?

Essential Materials for DTF Hat Printing

To start your DTF hat printing project, gather the following materials:

- DTF transfer film

- DTF powder adhesive

- Hat press machine designed for DTF transfers

- Clean fabric hats

- Protective Teflon sheets or parchment paper

Ensure you have a well-ventilated workspace and follow safety precautions while handling DTF materials.

How to Prepare Hats for DTF Transfers

Before applying DTF prints, prepare your hats by cleaning them thoroughly to remove dust and oils. Position the hats on the DTF hat press to ensure even heating and a smooth transfer surface.

Selecting the Perfect Design for Your DTF Hat

Choosing the right design is crucial for a successful DTF hat project. Consider the hat's color, style, and intended use. Popular choices include team logos, personalized initials, and bold graphic patterns.

Optimizing Your Hat Press for DTF Transfers

Set your hat press to the recommended temperature (around 300°F) and pressure settings. Follow manufacturer guidelines to ensure proper heat distribution and adherence of the DTF transfer to the hat fabric.

Also Read: 4th of July Shirt Ideas Using Ready to Press DTF Transfers

Step-by-Step Process for Applying DTF Prints to Hats

- Prepare the Design: Print your chosen design onto DTF transfer film.

- Apply Adhesive: Dust the printed design with DTF powder adhesive.

- Position the Hat: Place the hat on the hat press, ensuring the transfer area is flat and centered.

- Press the Transfer: Cover the design with a Teflon sheet and press for about 15-20 seconds.

- Peel Off Carefully: Remove the Teflon sheet and peel away the transfer film carefully to reveal the DTF print on the hat.

Ensure the hat cools completely before handling it to avoid smudging the print.

Maintaining Your DTF Printed Hats

To preserve your DTF prints, avoid washing the hats for at least 24 hours after application. Hand wash gently with mild detergent in cold water and air dry to extend the life of your custom designs.

Common Challenges and Solutions in DTF Hat Printing

Encountering issues like incomplete transfers or uneven colors? Adjust your DTF hat press settings or revisit the cleaning and preparation steps to achieve better results.

Innovative Ideas for Custom DTF Hats

Explore creative applications of DTF prints on hats, such as:

- Custom event giveaways

- Corporate branding

- Personalized gifts

- Limited edition merchandise

The versatility of DTF allows you to cater to various markets and personalization needs.

Safety Guidelines for Using a Hat Press

Always wear heat-resistant gloves and work in a well-ventilated area when using a hat press for DTF printing. Follow manufacturer instructions to avoid accidents and ensure consistent results.

Eco-Friendly Practices for DTF Hat Printing

Consider using eco-friendly materials and practices, such as biodegradable DTF films and water-based adhesives, to reduce environmental impact without compromising print quality.

Customizing hats with DTF prints opens up endless possibilities for creating unique, personalized upgrades. When for personal use, promotional items, or gifts, DTF printing ensures your designs stand out with vivid colors and durable quality.

Ready to transform your hats with DTF prints? Visit DTF NC to explore a range of DTF materials and start your custom hat projects today. Share your creations with our community and inspire others with your innovative designs. Let's make your hats unforgettable with DTF printing!

FAQs

What size DTF for hats?

DTF transfers for hats typically range from 2x2 inches to 4x4 inches, depending on the design and hat size.

Can you do a heat transfer on a hat?

Yes, heat transfers can be done on hats, but DTF printing offers superior detail and durability on fabric hats.

How long to press DTF on a hat?

Press DTF transfers on hats for approximately 15-20 seconds at a temperature of around 300°F for optimal adherence.

How to press the DTF logo onto a hat with a heat press?

Position the hat on the press, place the DTF logo facing down on the hat fabric, cover it with a Teflon sheet, and press according to the recommended settings.

Can you sublimation print on hats?

Sublimation printing is possible on hats but may not provide the same vibrant colors and detailed results as DTF printing on fabric hats.