Are you curious about customizing wood products using Direct to Film (DTF) transfers? You're in the right place! DTF transfers are revolutionizing the way we personalize wood, allowing for stunning, high-quality designs.

This guide will take you through everything you need to know to get started.

What is DTF?

Direct to Film (DTF) is a printing technique where designs are printed onto a special film and then transferred onto various surfaces, including wood, using heat. Unlike traditional methods like screen printing or vinyl, DTF offers vibrant colors and intricate details that last.

Why Choose DTF for Wood Products?

DTF transfers are ideal for wood because they adhere well and provide a durable, long-lasting finish. The versatility of DTF allows for custom designs that can be used for everything from decorative plaques to personalized gifts.

On Which Wooden Products Can DTF Printing Be Applied?

DTF printing is highly versatile and can be applied to a wide variety of wooden products, resulting in unique and personalized items. This technique is used on sports equipment, handmade products, photo frames, and much more. Here are some examples of wooden products that can be enhanced with DTF printing:

- Headboards

- Cabinets

- Art paintings

- Wedding, engagement, and entertainment accessories

- Tables

- Wooden ceiling tiles

- Handmade crafts

- Jewelry boxes

- Educational wooden puzzles

- Tennis rackets

- Baseball bats

Each item can be customized to create distinct and memorable designs.

Also Read: Can You Put DTF Prints on Hats?

Materials Needed for DTF on Wood

To get started with DTF on wood, you'll need the following materials:

- DTF transfer film

- DTF powder adhesive

- Heat press machine

- Smooth, clean wood surface

- Teflon sheet or parchment paper

You can find these materials at most craft stores or online.

Preparing Your Wood Surface

Before applying a DTF transfer, it's crucial to prepare your wood surface properly. Start by cleaning the wood to remove any dust or debris. Sand the surface until it's smooth, ensuring the transfer adheres evenly.

Choosing the Right DTF Transfer Design

Selecting the right design is key to a successful project. Consider the wood's color and grain pattern when choosing your design. Popular ideas include intricate patterns, personalized text, and nature-inspired graphics.

Setting Up Your Heat Press

For optimal results, set your heat press to the correct temperature and pressure. Typically, a temperature of 325°F (163°C) and medium pressure work well for wood transfers. Always refer to the specific instructions provided with your DTF materials.

Step-by-Step Guide to Applying DTF Transfers

- Print your design on the DTF transfer film.

- Apply the adhesive powder to the printed design.

- Place the transfer on the wood surface with the printed side down.

- Cover with a Teflon sheet to protect the transfer.

- Press with heat for about 20 seconds.

- Remove the film carefully, ensuring the design has adhered completely.

Avoid common mistakes like overheating or uneven pressure, which can affect the transfer quality.

Post-Transfer Care

To ensure your design lasts, consider sealing it with a clear coat. This protects the transfer from scratches and wear. Regular dusting and gentle cleaning will keep your wood piece looking new.

Creative Ideas for DTF on Wood Projects

The possibilities with DTF on wood are endless! Create personalized name plaques, custom cutting boards, or unique wall art. These make fantastic gifts and add a personal touch to your home decor.

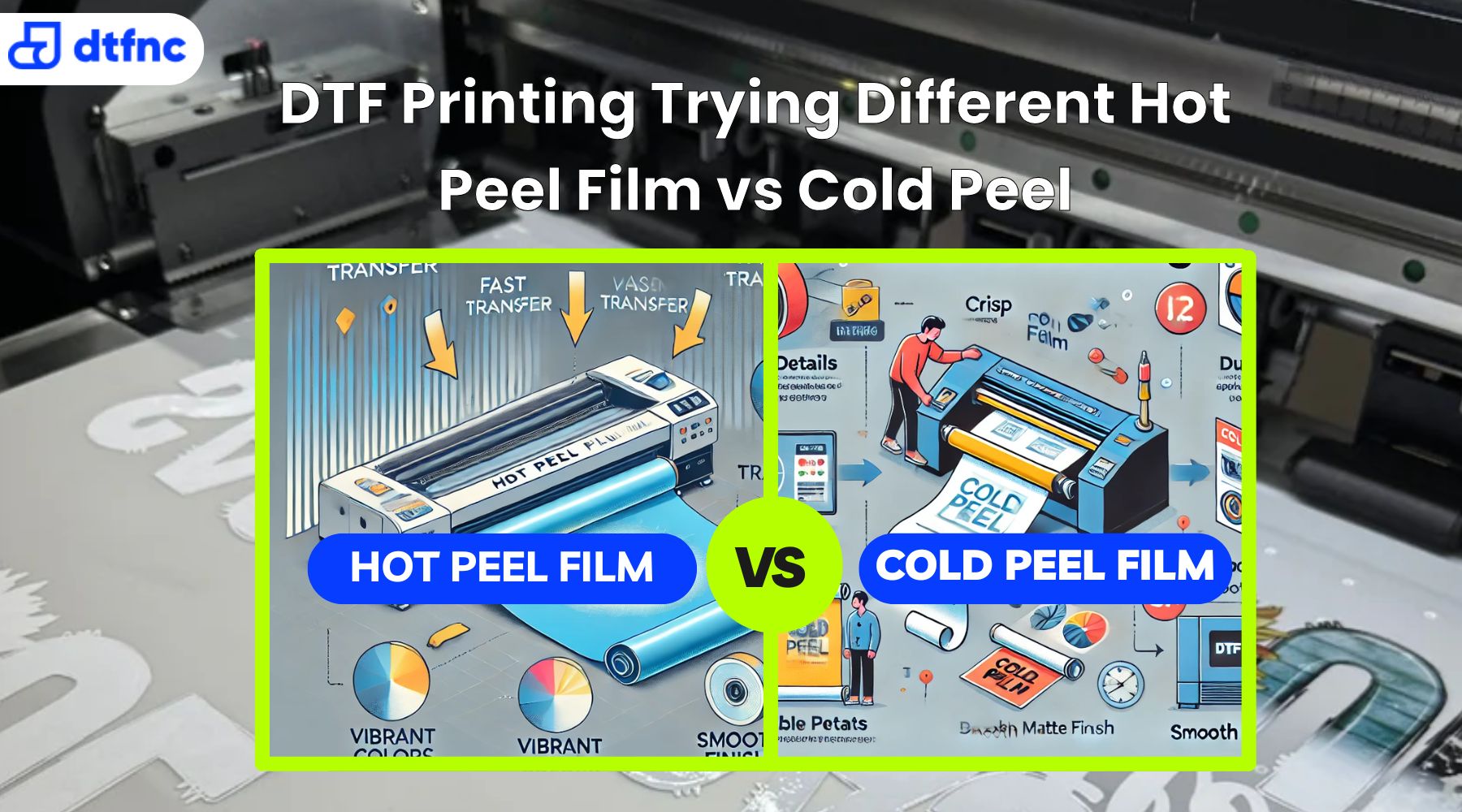

Also Read: Hot Peel Application Instructions

Safety Tips for Using a Heat Press on Wood

Always use your heat press in a well-ventilated area and follow the manufacturer's safety guidelines. Wear heat-resistant gloves and keep flammable materials away from your work area to prevent accidents.

Environmental Considerations

Consider using eco-friendly wood and non-toxic adhesives for a more sustainable crafting practice. Recycling or repurposing old wood can also reduce waste and create unique, rustic pieces.

Customizing wood products with DTF transfers opens up a world of creative possibilities. With the right materials and techniques, you can create beautiful, personalized pieces that stand out. So, why not give it a try? Your next masterpiece is just a heat press away!

Ready to transform your wood projects with DTF? Visit DTFNC for all the tools and materials you need to get started. Share your creations with our community and inspire others with your unique designs. Let's create something amazing together!

FAQs

1- What temperature is DTF on wood?

The ideal temperature is usually around 325°F (163°C).