Direct-to-Film (DTF) printing has gained immense popularity in the world of custom clothing and textile decoration. It offers a versatile and cost-effective way to create high-quality prints on various fabrics. However, like any printing method, DTF transfers can face challenges, one of the most common being the transfer not sticking as desired.

In this blog post, we will explore the possible reasons behind DTF transfer not sticking and provide solutions to fix this issue.

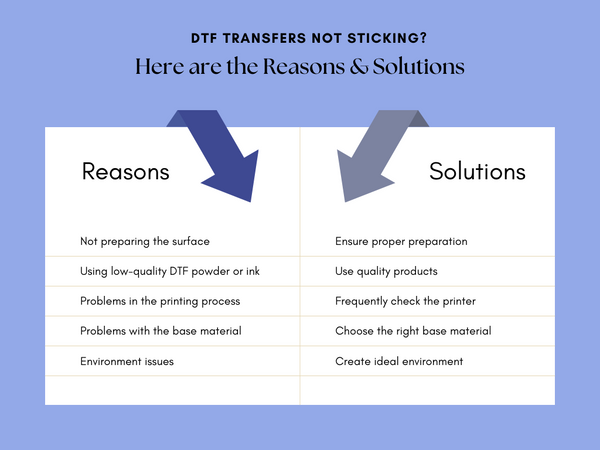

Possible Reasons for DTF Transfer Not Sticking

Here are some common reasons why DTF transfers may not be sticking properly:

Inadequate Pre-Treatment of the Substrate

Proper pre-treatment of the substrate is crucial for successful DTF transfers. When the substrate is not adequately pre-treated, it may not provide the right surface for the ink or powder to adhere to. Inadequate pre-treatment can lead to poor adhesion and transfer failure.

Heat Press: Pressure Issue

DTF transfers require firm pressure for a good adherence. If the pressure is not at a desired level, you will start having the transfers cracking or lifting up with each wash. Make sure to have your pressure at firm. Ideally 70psi would be a good pressure level.

Poor Quality DTF Powder or Ink

The quality of the DTF powder or ink plays a significant role in the adhesion of the transfer. Low-quality or expired powders/inks may not adhere well to the substrate, resulting in a transfer that doesn't stick properly. It's essential to use high-quality and compatible materials for DTF printing.

Issues with the Printing Process

DTF printing involves several variables, such as temperature, pressure, and print settings. If any of these factors are not set correctly, it can affect the adhesion of the transfer. Issues like incorrect curing temperature, inadequate pressure, or improper curing time can lead to transfer failure.

Substrate-Related Issues

The type and quality of the substrate used for DTF transfers also matter. Different fabrics have different surface properties, and some may require specific pre-treatment methods or adjustments to the printing process to ensure proper adhesion. Using the wrong substrate for your DTF transfer can result in non-sticking transfers.

Environmental Factors

Environmental conditions can have a significant impact on the success of DTF transfers. Factors such as humidity, temperature, and ventilation can affect the drying and curing of the ink or powder. Inconsistent environmental conditions can lead to transfer issues.

Now, let's explore solutions for addressing the issue when DTF transfers are not sticking properly.

Read More: How to Store DTF Transfers: A Step-by-Step Guide

How to Fix the Problem of DTF Transfer Not Sticking?

To address the issue of DTF transfer not sticking, it's essential to identify the root cause and implement the appropriate solutions. Here are some steps to help you fix the problem:

Making Sure of Proper Pre-Treatment of the Substrate

- Clean and Prepare the Substrate: Ensure that the fabric or material you're printing on is clean and free from any contaminants like oils, dust, or residue.

- Apply the Right Pre-Treatment: Use the appropriate pre-treatment solution for the specific substrate you're working with. Follow manufacturer recommendations for application and drying.

- Dry and Cure the Pre-Treatment: Make sure the pre-treatment is thoroughly dried and cured before proceeding with the printing process. Insufficient drying can lead to transfer adhesion problems.

Regularly Testing and Replacing Low-Quality DTF Powder or Ink

- Source High-Quality Materials: Always purchase DTF powder and ink from reputable suppliers known for their quality. Verify that the materials are within their expiration date.

- Perform Quality Checks: Regularly test your DTF materials to ensure they meet your expectations in terms of color vibrancy and adhesion.

Choosing the Right Substrate for the DTF Transfer

- Match Substrate to Ink/Powder: Ensure that the substrate you choose is compatible with the specific DTF ink or powder you are using. Some inks and powders work better on certain fabrics.

- Consider Surface Texture: The texture of the fabric can affect adhesion. Experiment with different substrates to find the one that works best for your DTF transfers.

Optimizing the Printing Process

- Calibrate Your Printer: Ensure that your DTF printer is correctly calibrated. This includes setting the right resolution, ink density, and other print parameters.

- Temperature and Pressure Control: Monitor and adjust the curing temperature and pressure settings to match the requirements of your DTF materials and substrate.

- Proper Curing Time: Ensure that the ink or powder is exposed to the correct curing time to ensure optimal adhesion.

Now that we've explored the issues and their solutions regarding DTF transfer sticking, let's move on to see how to optimize the DTF printing process.

Also Read: How to Press DTF Transfers on T-shirts

How to Optimize the Printing Process?

Optimizing the printing process is critical for achieving successful DTF transfers. Here are some steps to help you achieve the best results:

- Printer Maintenance: Regularly clean and maintain your DTF printer to prevent nozzle clogs and other issues that can affect print quality.

- Color Management: Use color management software to ensure accurate color reproduction and consistency across prints.

- Test Prints: Before starting a production run, perform test prints to fine-tune settings and ensure that the colors and adhesion meet your standards.

- Follow Manufacturer Guidelines: Always refer to the manufacturer's guidelines for your specific DTF printer and materials.

These guidelines often provide valuable insights into optimal settings and procedures.

Why Choose DTF NC for DTF Transfers?

We, at DTFNC, are a leading company specializing in DTF printing, offering several compelling reasons to choose us for your DTF transfers. Our team brings a wealth of expertise and dedication to the field, ensuring top-notch guidance and support.

DTFNC employs cutting-edge DTF technology, for superior adhesion, vibrant colors, and durability. We stand out for our versatility in handling various materials and our commitment to seamless integration into your workflow. When you opt for DTFNC, you're selecting a partner dedicated to delivering exceptional results in the world of DTF printing.

FAQs

1. Why Is My DTF Transfer Not Sticking to the Substrate?

There can be several reasons for this issue, including inadequate pre-treatment, poor-quality materials, printing process problems, substrate-related issues, or environmental factors. Follow the troubleshooting steps outlined in this blog post to identify and address the specific cause of the problem.

2. How Can I Properly Pre-Heat the Substrate?

Properly pre-heating the substrate involves using the correct pre-treatment solution and ensuring it is thoroughly dried and cured before printing. Follow the manufacturer's instructions for the pre-treatment product you are using and use a heat press or curing unit with the recommended settings.

3. What Can I Do If I Am Using High-Quality Powder or Ink, and My DTF Transfer Is Still Not Sticking?

If you're using high-quality DTF powder or ink, but your transfer isn't sticking, consider checking substrate pre-treatment, optimizing printing parameters, monitoring environmental conditions, evaluating substrate compatibility, maintaining equipment, reviewing design preparation, and exploring the use of DTF NC for enhanced adhesion. If issues persist, consult your material manufacturer or supplier for guidance.

4. Can Environmental Factors Affect the Sticking of DTF Transfers?

Yes, environmental factors can significantly affect the sticking of DTF transfers. Variables such as humidity, temperature, and ventilation can impact the drying and curing of DTF ink or powder. Inconsistent environmental conditions may lead to adhesion issues, emphasizing the need for a controlled and stable printing environment.

5. What Can I Do if My DTF Transfer Is Not Sticking Even After Trying Different Solutions?

If your DTF transfer continues to have adhesion problems despite troubleshooting efforts, consider the following steps:

- Revisit all troubleshooting steps and verify that each element has been thoroughly addressed.

- Consult with an experienced DTF printing professional or seek guidance from the manufacturer or supplier of your DTF materials.

- Explore alternative DTF materials or technologies, as there may be specific compatibility issues or limitations with the materials you are currently using.

Sometimes, persistent adhesion problems may require a fresh perspective or specialized expertise to identify and resolve the underlying issue.

5 comments

mdsqqzhmpl

Why Is My DTF Transfer Not Sticking? How to fix it? – DTF North Carolina

amdsqqzhmpl

mdsqqzhmpl http://www.g94w0a1e8xe6t009a5td405553odvblns.org/

[url=http://www.g94w0a1e8xe6t009a5td405553odvblns.org/]umdsqqzhmpl[/url]

Richard

My DTF Transfers are not sticking on certain shirts, I have the pressure on my heat press set at 30psi the temp at 315 and 15secs of pressing time.

Leticia

I’m need dtf logo 2″×2″

24 logos

What is the page price.

Felix Meyer

You made some really good points on your post. Definitely worth bookmarking for revisiting. Also, visit my website Webemail24 for content about Rental Car Services.

Timothy Osburn

Will definitely transfers fork on non flat painted polypropylene?